Group progress

Company history

Value creation history

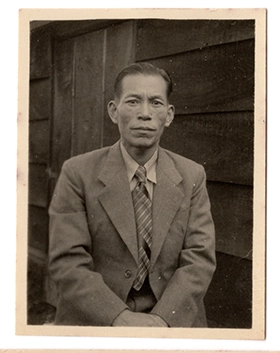

1899

Founder Chikashi Taniguchi is born in Fukui, Fukui Prefecture.

Founder Chikashi Taniguchi

Chikashi joins Tokyo Kizai Kogyo Works, which later becomes Takasago Tekko K.K.

Chikashi joins Tokyo Kizai Kogyo Works, which later becomes Takasago Tekko K.K.

1919

Chikashi moves by himself to Tokyo at age 15 and polishes his skills as a cold-rolling technician. Taking a cue from U.S.-made rolling machines, Chikashi designs and fabricates what at the time is a cutting-edge rolling machine based on his own ideas.

The Company participates in the founding of Tokyo Shintetsu Works, which later becomes Nippon Kinzoku Co., Ltd.

1930

The Company establishes Tokushu Kinzoku Rolling Works in Itabashi (Maeno-cho, Itabashi-ku) in May.

1940

The Company establishes the best reputation in Japan for high-quality special steel materials for precision springs.

1947

Founder Chikashi Taniguchi is awarded the Komura Prize (Technical Achievement Award) by The Iron and Steel Institute of Japan for his contributions to the design of rolling mills for the production of cold-rolled steel strips and for improving product precision.

The Company is reorganized to form Tokushu Kinzoku Kogyo Co., Ltd. with capital of ¥1.5 million in May.

Following the end of World War II, the Company builds an annealing plant, which becomes Tokyo’s first steel-framed building.

Following the end of World War II, the Company builds an annealing plant, which becomes Tokyo’s first steel-framed building.

1948

1952

The Company starts producing cold-rolled stainless steel strip.

1956

The Company establishes technology for manufacturing ultra-thin cold-rolled steel foil with a thickness of 10 microns for use as camera shutter blades.

The Company increases its capital to ¥200 million.

The Osaka Sales Office opens in Higashi-ku, Osaka.

The Osaka Sales Office opens in Higashi-ku, Osaka.

1965

1967

The Company licenses cold-rolling technology to Hankook Metal Industrial Co., Ltd. (present-day Hankum Co., Ltd.).

Founder Chikashi Taniguchi is awarded the Academia Prize by The Academic Society of Japan for his contributions to the research and application of thin special steel rolling mills, by means of which he advanced the state of the industry and improved the public welfare.

The Company receives the Tokyo Governor’s Prize in recognition for its contributions to the advancement of science and technology.

Founder Chikashi Taniguchi is awarded the Academia Prize by The Academic Society of Japan for his contributions to the research and application of thin special steel rolling mills, by means of which he advanced the state of the industry and improved the public welfare.

The Company receives the Tokyo Governor’s Prize in recognition for its contributions to the advancement of science and technology.

1968

Founder Chikashi Taniguchi is awarded the Medal with Purple Ribbon in recognition of his achievements in developing cold rolling mills for ultra-thin steel strip.

Founder Chikashi Taniguchi passes away.

Chikashi is posthumously awarded the Order of the Rising Sun, Gold Rays with Rosette, in recognition of lifetime achievements.

Eiichi Taniguchi becomes president.

Chikashi is posthumously awarded the Order of the Rising Sun, Gold Rays with Rosette, in recognition of lifetime achievements.

Eiichi Taniguchi becomes president.

1970

The Company achieves top market share in the export of high carbon steel strip for razors.

Nagano Tokushu Kinzoku Kogyo Co., Ltd. is established.

1973

Osaka Tokkin Shoji Co., Ltd. is established. Fukui Tokushu Kinzoku Kogyo Co., Ltd. is established.

1974

1980

The Company achieves top market share in the supply of stainless steel for use in headphones.

The Company achieves the highest standards in fatigue strength for stainless steel for springs used in automotive seat belts.

The Company increases its capital to ¥320 million.

The Company launches an employee stock ownership plan.

The Company launches an employee stock ownership plan.

1981

The Company begins developing materials for use in the metal hubs of 3.5-inch floppy disks.

Saitama Tokushu Kinzoku Kogyo Co., Ltd. (the present-day Saitama Factory) is established.

1982

The Company begins operating the world’s first rolling mill equipped with ZH inserts (18-roll configuration).

1985

The Company captures a significant share of the market for suppressing springs for VTR cassettes.

The Company starts manufacturing 10-micron thick, 300-millimeter wide stainless steel foil.

The Company starts manufacturing 10-micron thick, 300-millimeter wide stainless steel foil.

The Company starts consolidating its production equipment at facilities operated by Saitama Tokushu Kinzoku Kogyo Co., Ltd.

1986

Yoshito Taniguchi becomes president.

1987

The Company achieves top market share in materials designed for use in metal hubs.

The Company starts producing stainless steel foil.

The Company starts producing stainless steel foil.

Taiwan Tokkin Co., Ltd. starts operations.

1988

The Company is ranked among the top five manufacturers of materials used in measuring tapes.

Kanji Fujisawa compiles technological systems for rolling, annealing, and cutting into a publication entitled “Plastic Processing.”

Kanji Fujisawa compiles technological systems for rolling, annealing, and cutting into a publication entitled “Plastic Processing.”

The Company absorbs Osaka Tokkin Shoji Co., Ltd. and Saitama Tokushu Kinzoku Kogyo Co., Ltd.

The Sales Department, General Affairs Department, and Financial Affairs Department are relocated to Ikebukuro.

The Company enters into an operational alliance with JCM Co., Ltd.

The Sales Department, General Affairs Department, and Financial Affairs Department are relocated to Ikebukuro.

The Company enters into an operational alliance with JCM Co., Ltd.

1990

The Company starts developing and marketing composite materials using clad bonding.

An expansion of Fukui Tokushu Kinzoku’s plant is completed, and some of the machinery from the Head Office is moved to Fukui.

Construction of the Coil Center and R&D Center at the Saitama Factory is completed.

Construction of the Coil Center and R&D Center at the Saitama Factory is completed.

1991

1992

The Company starts shipping a functional-resin coated material (OVIONE™).

1993

The Company decides to develop the site of the former Head Office Plant as a tenant-occupied building.

1994

The Company demolishes the Head Office Plant. Construction of Izumiya starts.

La Folia Izumiya opens in Maeno-cho.

The Company acquires shares of Kanto Kinzoku to make it an affiliate.

The Company withdraws from the Cold Rolled Steel Strip Promotion Association.

The Tohoku Sales Office opens.

The Company acquires shares of Kanto Kinzoku to make it an affiliate.

The Company withdraws from the Cold Rolled Steel Strip Promotion Association.

The Tohoku Sales Office opens.

1995

Material manufactured by the Company is chosen for use in precision electronic components for the first time.

The Company establishes a wholly owned subsidiary in Shanghai.

The sales team and Head Office functions are relocated to and consolidated in Mejiro.

The sales team and Head Office functions are relocated to and consolidated in Mejiro.

1996

Construction of a building for Shanghai Tokkin Co., Ltd. starts.

1997

A prototype patenting steel strip exceeds global standards.

Shanghai Tokkin Co., Ltd. starts operations.

The Suwa Sales Office is reorganized to form Y.K. Material Co., Ltd.

The Tsurugashima Dormitory is built to provide housing for single employees.

The Suwa Sales Office is reorganized to form Y.K. Material Co., Ltd.

The Tsurugashima Dormitory is built to provide housing for single employees.

1998

The Company absorbs the manufacturing division of JCM Co., Ltd. and establishes the Composite Materials Department.

The Company earns ISO 9001 certification for all its domestic offices and factories.

Taiwan Tokkin is named in a steel dumping lawsuit in the U.S.

The Company earns ISO 9001 certification for all its domestic offices and factories.

Taiwan Tokkin is named in a steel dumping lawsuit in the U.S.

1999

The Company starts manufacturing composite materials with cladding, soldering, and coating technologies at their core.

Tokkin Kinzoku Excel Co., Ltd. is established. The Company absorbs Fukui Tokushu Kinzoku Kogyo Co., Ltd.

The Fukui Factory and Akabane Factory start operations.

Shanghai Tokkin Precision Molds Co., Ltd. is established.

The Company launches a companywide networking and information system.

The Fukui Factory and Akabane Factory start operations.

Shanghai Tokkin Precision Molds Co., Ltd. is established.

The Company launches a companywide networking and information system.

2000

OVIONE™, a pre-coat material with insulation functionality, is chosen for use in precision electronic components.

The Tohoku Sales Office and Akabane Factory close.

2001

The Company starts manufacturing metal materials for shunt resistors.

The Fukui Factory closes, and the Company absorbs Nagano Tokushu Kinzoku Kogyo Co., Ltd.

Equipment and production from Fukui is reallocated Shanghai and Saitama as the Company reorganizes its businesses.

The Nagano Sales Office opens.

Equipment and production from Fukui is reallocated Shanghai and Saitama as the Company reorganizes its businesses.

The Nagano Sales Office opens.

2002

The Company starts developing ultra-fine-grain refinement technology for stainless steel in joint research with the National Institute for Materials Science and Komatsuseiki Kosakusho Co., Ltd.

2003

The company provided fine-grained structure with bell-type furnaces built in Saitama.

Manufacturing and sales are integrated and consolidated into cold-rolled materials and composite materials businesses to realize a throughput-oriented structure. The Company reviews its approach to inventory quantity and management.

Manufacturing and sales are integrated and consolidated into cold-rolled materials and composite materials businesses to realize a throughput-oriented structure. The Company reviews its approach to inventory quantity and management.

2004

The Company launches Tokkin Innovation Activities (to spur innovation in production) after receiving guidance on Toyota-style production innovation from OJT Solutions.

The Company adopts a new corporate organization with executive officers.

The Company adopts a new corporate organization with executive officers.

Saya-no-yudokoro Co., Ltd. the Company's hot spring business, opens.

2005

The Company develops a facility management system using automatic checkout machines.

2006

The Company launches a full-fledged “Creativity and Ingenuity” program.

The Company earns ISO 14001 certification.

The Company earns ISO 14001 certification.

The Tokkin Mission Statement is formulated.

The Shanghai Phase 2 plant expansion is completed. Shanghai Xiyin Composite Material Co., Ltd. is established.

The Shanghai Phase 2 plant expansion is completed. Shanghai Xiyin Composite Material Co., Ltd. is established.

2007

The Company launches a B2B corporate website with integrated web marketing features.

The Company absorbs Tokkin Kinzoku Excel Co., Ltd. and changes its name from Tokushu Kinzoku Kogyo Co., Ltd. to Tokkin Kinzoku Excel Co., Ltd. The Head Office is relocated to Mejiro.

2008

The Company successfully prototypes ultra-fine-grain stainless steel strip using a combination of cold rolling and clad rolling.

The Company successfully prototypes ultra-fine-grain stainless steel strip using repeated cycles of cold rolling and reverse transformation using actual production equipment.

The Company exhibits its products for the first time in Japan at the New Functional Materials Expo (Tokyo Big Sight).

The Saitama Factory earns OHSAS 18001 certification.

The Company successfully prototypes ultra-fine-grain stainless steel strip using repeated cycles of cold rolling and reverse transformation using actual production equipment.

The Company exhibits its products for the first time in Japan at the New Functional Materials Expo (Tokyo Big Sight).

The Saitama Factory earns OHSAS 18001 certification.

2009

The Company is selected to participate in “Development of a Joint Interface Evaluation System for Metal Clad Strips,” a project under the Strategic Core Technology Advancement Program.

The Company opens an online store selling stainless steel foil.

The Company opens an online store selling stainless steel foil.

Yoshito Taniguchi becomes chairman. Tsuyoshi Taniguchi becomes president.

A CCD inspection line is installed at Taiwan Tokkin.

A CCD inspection line is installed at Taiwan Tokkin.

2010

Ultra-fine-grain stainless steel is chosen for the first time for use in automotive fuel injectors (electronically controlled injection systems).

Development of tailored strip manufacturing technology for automotive fixed resistors is permitted by the Act on Enhancement of Small and Medium Sized Enterprises' Core Manufacturing Technology.

Development of tailored strip manufacturing technology for automotive fixed resistors is permitted by the Act on Enhancement of Small and Medium Sized Enterprises' Core Manufacturing Technology.

The end of the Company’s fiscal year is changed from March to December.

Hong Kong Tokkin Kinzoku Excel Co., Ltd. is established.

A medium-term business plan takes effect across the entire Tokkin Group.

Hong Kong Tokkin Kinzoku Excel Co., Ltd. is established.

A medium-term business plan takes effect across the entire Tokkin Group.

2011

The Company develops stainless steel materials for flexible printed circuits (FPCs) used in mobile phones.

The Company develops ultra-high-strength thin steel sheets for use in haptic devices. The material features processing brittleness resistance and high-cycle fatigue durability.

The Company develops ultra-high-strength thin steel sheets for use in haptic devices. The material features processing brittleness resistance and high-cycle fatigue durability.

Tamagawa Kosan Co., Ltd. changes its name to Mamori Co., Ltd.

The Tohoku Sales Office opens.

The Tohoku Sales Office opens.

2012

Saya-no-yudokoro Co., Ltd. undergoes renovations. The “Sakura” and “Omoto” private rooms are added to the facility.

The Company develops ultra-fine-grain manufacturing technology for high-carbon steel.

The Company develops ultra-fine-grain manufacturing technology for high-carbon steel.

The Head Office is relocated to Mejiro. The Company launches a strategic project led by a dedicated team. The Quality Innovation Activities 108 (QIV108) initiative is launched.

The Company formulates a business continuity plan (BCP).

Construction of Plant No. 3 at the Saitama Factory is completed.

The Company formulates a business continuity plan (BCP).

Construction of Plant No. 3 at the Saitama Factory is completed.

2013

The Company is selected to participate in “Development of Processing Technology for Nano-precision Microcomponents Utilizing the Superplasticity Effects of SUS304,” a project under the Strategic Core Technology Advancement Program.

The Company enters the market for seal components used in hermetically sealed bellows.

The Company cancels its OHSAS 18001 certification and continues related activities on a voluntary basis.

The Company enters the market for seal components used in hermetically sealed bellows.

The Company cancels its OHSAS 18001 certification and continues related activities on a voluntary basis.

2014

The Company launches an effort to formulate an intellectual property strategy with support from the Tokyo Metropolitan Government.

AEON Style Itabashi Maeno-cho opens.

2015

Saya-no-yudokoro Co., Ltd. undergoes renovations. "Hanare-no-yu Akari" opens.

After receiving a new manufacturing, commercial, and service subsidy, the Company makes modifications to achieve low-tension control in tension annealing (TA).

After receiving a new manufacturing, commercial, and service subsidy, the Company makes modifications to achieve low-tension control in tension annealing (TA).

2016

The Company is chosen as one of the top 200 leading companies in Tokyo by the Tokyo Metropolitan Small and Medium Enterprise Support Center.

The Company launches the “Be a Niche-TOP!®” sales strategy.

The Company launches the “Be a Niche-TOP!®” sales strategy.

Tokkin Kinzoku Excel Co., Ltd. changes its name to Tokkin Holdings Corp., and Tokkin Kinzoku Excel Co., Ltd. is formed by means of a corporate split.

2017

The Company is chosen to participate in the Tokyo Metropolitan Small and Medium Enterprise Support Center’s Global Niche Top Support Program.

The Company exhibits its products in Europe for the first time at COMPAMED 2017 (in Dusseldorf).

The Company exhibits its products in Europe for the first time at COMPAMED 2017 (in Dusseldorf).

2018

Tokkin 350 JIN™ receives the 41st Technical Development Award from The Japan Institute of Metals and Materials.

2019

The Company develops high-carbon cold-rolled steel sheets for use in premium latch needles. The product delivers excellent impact and hardness characteristics as well as outstanding wear resistance.

2020

The Company starts supplying composite functional materials manufactured using the cold spray (CS) method.

The Company expands its high-strength, high-ductility stainless steel (JIN™) and ultra-fine-grain steel (nanoSUS™) lines of products.

Solar panels are installed at the Saitama Factory.

The Company expands its high-strength, high-ductility stainless steel (JIN™) and ultra-fine-grain steel (nanoSUS™) lines of products.

Solar panels are installed at the Saitama Factory.

Tokkin Singapore Pte. Ltd. is established.

2021

The Company establishes technology for improving the surface corrosion resistance of SUS301.

Tokkin Singapore Pte. Ltd. starts operations.

Tokujiro Mizutani becomes president of Tokkin Kinzoku Excel Co., Ltd.

Tokujiro Mizutani becomes president of Tokkin Kinzoku Excel Co., Ltd.

2022

The Company develops high-strength magnetic stainless steel.

The Company is approved for a subsidy grant for investment in cold-rolling mill to enhance competitiveness by the Tokyo Metropolitan Small and Medium Enterprise Support Center.

The Company is approved for a subsidy grant for investment in cold-rolling mill to enhance competitiveness by the Tokyo Metropolitan Small and Medium Enterprise Support Center.

Construction of a new plant in Nagano is completed.

2023

Saya-no-yudokoro Co., Ltd. undergoes renovations to facilitate greater social distancing.

The Company expands the range of its manufacturing capabilities for nanoSUS™, an ultra-fine-grain stainless steel for which the diameter of crystal grain in its metal structure has been refined to approximately 1 micrometer.

The Mejiro Head Office and Saitama Factory undergo renovations. The solar system has generated 1.2 million kilowatt-hours.

The Company earns certification under the ISO/IEC 27001:2013 international standard and the JIS Q 27001:2014 Japanese standard. The two standards, both of which require third-party certification, govern information security.

The Company expands the range of its manufacturing capabilities for nanoSUS™, an ultra-fine-grain stainless steel for which the diameter of crystal grain in its metal structure has been refined to approximately 1 micrometer.

The Mejiro Head Office and Saitama Factory undergo renovations. The solar system has generated 1.2 million kilowatt-hours.

The Company earns certification under the ISO/IEC 27001:2013 international standard and the JIS Q 27001:2014 Japanese standard. The two standards, both of which require third-party certification, govern information security.

Tokkin Kinzoku Excel Co., Ltd. launches a corporate branding initiative.

The Tokkin Holdings logo is redesigned.

The Tokkin Holdings logo is redesigned.

2024

The Company starts cold rolling production with high recycled raw material content.

The Company establishes mass production manufacturing technology for ultra-thin foil as thin as 2 micrometers.

The Company establishes mass production manufacturing technology for ultra-thin foil as thin as 2 micrometers.